Recycling Aramids - Mechanical Processing

Aramid fibers, such as Kevlar and Nomex, are high-strength, heat-resistant synthetic fibers commonly used in various applications, including protective gear, aerospace and automotive parts, and high-performance sporting goods. Aramid fibers are highly durable and can withstand extreme conditions, which makes them suitable for long-term use. However, when they reach the end of their useful life, recycling these fibers can be challenging due to their unique properties.

Aramid fibers are made of long-chain polymers that are difficult to break down chemically, making traditional recycling processes challenging. However, some efforts have been made to recycle aramid fibers by mechanical and chemical recycling processes.

Mechanical recycling of aramid fibers involves the physical breakdown of the fibers into smaller particles or fibers that can be used as a reinforcement material in the production of new composite materials or plastics. The mechanical recycling process for aramid fibers typically involves the following steps:

-

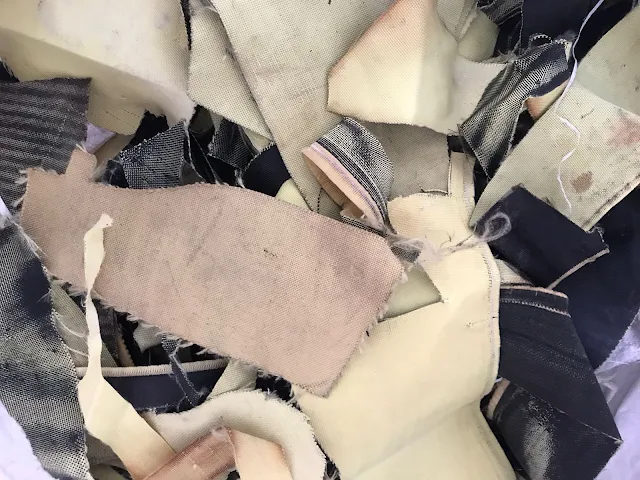

Collection: Aramid fibers are collected from end-of-life products or industrial waste streams.

-

Sorting: The collected fibers are sorted based on their quality and characteristics, such as fiber length, color, and degree of wear.

-

Cutting: The sorted fibers are then cut into small pieces or fibers using cutting machines or grinding mills. The size of the resulting fibers can vary depending on the application and requirements.

-

Blending: The aramid fibers are then blended with other materials such as thermoplastics, thermosets, or resins to create a composite material.

-

Processing: The blended material is then processed using standard techniques such as injection molding, extrusion, or compression molding to produce the final product.

Re-spinning of recovered fibbers is another alternative. The process of respinning aramid fibers into yarn involves several steps. First, the recovered aramid fibers are collected, sorted, and cleaned to remove any contaminants or impurities. The fibers are then carded or combed to align them in a consistent direction and remove any tangles or knots. The carded or combed fibers are then spun into yarn using spinning machines or techniques.

The resulting aramid yarn can be used in various applications, including the production of new protective gear, high-performance fabrics, and industrial materials. However, it is essential to note that the properties of the recycled aramid yarn may differ from those of the virgin fibers. The mechanical recycling process can weaken the fibers and decrease their strength, which may limit their suitability for high-performance applications. Therefore, recycled aramid yarn is typically used in applications where high strength and durability are not critical, such as in the production of low-stress fabrics or textiles.

Overall, the mechanical recycling of aramid fibers provides a viable solution for diverting end-of-life aramid products from landfills and reducing the environmental impact of aramid fiber waste. While it may not be suitable for high-performance applications, it can be used in a wide range of industrial and commercial applications, including automotive parts, construction materials, and consumer goods.

To discuss recycling opportunity of high performance fibres, visit https://kamlatech.in/