Sustainable Stretch Filaments NEOLAST™

NEOLAST™ fiber is designed to revolutionize performance stretch fabrics, offering a sustainable alternative to traditional elastane, commonly known as spandex.

NEOLAST™ fibers bring together powerful stretch, durability, comfort, and improved moisture-wicking capabilities, aligning with the high standards set by elite performance fabrics. What sets NEOLAST™ apart is its dedicated effort to address sustainability challenges associated with elastane, especially in terms of recyclability. The production process of NEOLAST™ fibers is notable for its use of a proprietary solvent-free melt-extrusion method, eliminating potentially hazardous chemicals typically found in the creation of stretch fabrics with elastane. A significant stride towards sustainability is the incorporation of recyclable elastoester polymers in the production of NEOLAST™ fibers. This move addresses the challenge of recycling fabrics containing elastane, a critical consideration as the industry moves towards a circular economy. Efforts are being made to explore how NEOLAST™ can enhance the compatibility of stretch fabrics with future recycling systems and infrastructure.

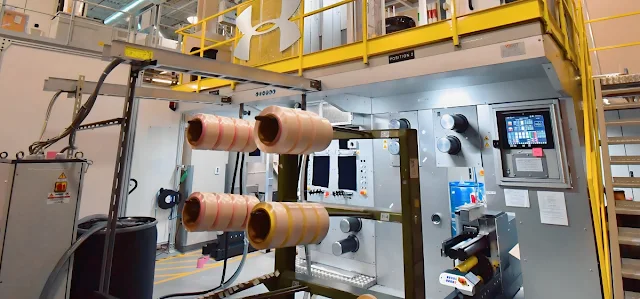

In addition to the sustainability benefits, the new NEOLAST™ fibers deliver increased production precision, allowing spinners to dial power-stretch levels up or down and engineer fibers to meet a broader array of fabric specifications.

A groundbreaking aspect of NEOLAST™ is its potential to unlock circular manufacturing for performance stretch fabrics. This innovation introduces the possibility for end-users to recycle these fabrics, addressing a challenge that has persisted until now. The collaboration focuses not only on introducing a new fiber, but also on paving the way towards circularity in textile manufacturing.

Innovate with Kamlatech