Baghouse Filter Specification

In the previous post, we discussed the use of Glass fabric and more specifically Glass PTFE fabric as a hot gas filtration media in power plants. These fabric filters are commonly referred to as Baghouse filters.

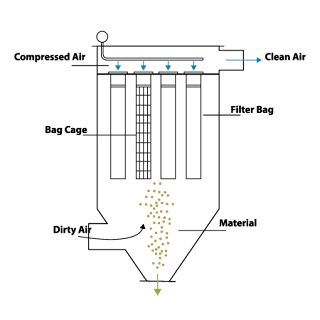

Baghouse filters, also known as fabric filters, are a type of air pollution control equipment that are commonly used in coal-fired power plants to capture pollutants from flue gases. The specific design and specifications of a baghouse filter will depend on the specific application and the pollutants that need to be removed from the flue gases.

Baghouse Design

Specification of Baghouse Filter

Flow rate: The flow rate of the flue gases through the filter is an important factor to consider, as it will determine the size and capacity of the filter. The flow rate is typically measured in cubic meters per minute (m3/min) or cubic feet per minute (cfm).

Temperature: The temperature of the flue gases passing through the filter is another important factor to consider, as it will determine the materials and construction of the filter. The filter should be able to withstand the temperature of the flue gases without degrading or failing.

Particulate matter: The filter should be able to capture a certain percentage of particulate matter from the flue gases, typically in the range of 95-99%. The efficiency of the filter can be measured by the size of the particulate matter that it is able to capture, with smaller particles being more difficult to capture.

Pressure drop: The pressure drop across the filter, also known as the resistance to airflow, is an important factor to consider, as it can affect the performance of the filter and the overall efficiency of the power plant. The pressure drop should be kept as low as possible to minimize energy consumption.

Cleaning method: The filter should be equipped with a system for cleaning the filter bags and removing the captured pollutants. This can be done mechanically, using shaking or vibrating systems, or pneumatically, using compressed air.

Example

- Flow rate: 60,000 m3/min

- Temperature: Up to 250 degrees Celsius

- Particulate matter removal efficiency: 99% for particles smaller than 2.5 microns

- Pressure drop: Less than 100 Pa

- Cleaning method: Mechanical shaking system

- Filter media: Glass fiber fabric with PTFE coating

Apart from this, number of bags and bag dimension are decided to calculate final filtration area.

Hope this information is useful. See you latter, Till then stay safe, wear mask and save soil