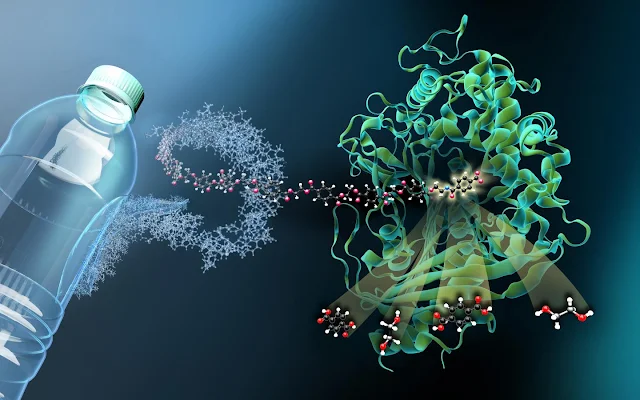

Xenon Arc vs. MBTL Lamps for Color Fastness Testing

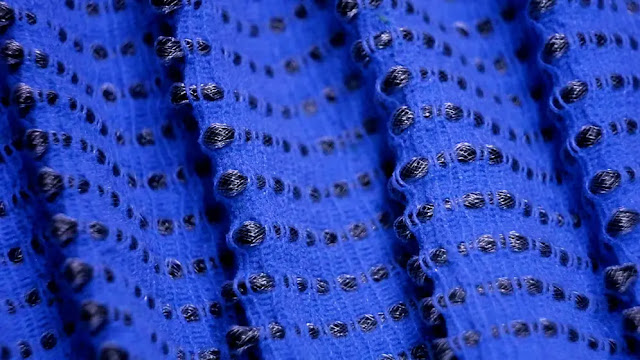

When we talk about the color fastness of textiles, especially how they react to light, the type of light source used for testing is very important. Standards like BS EN ISO 105-B02:2014 are in place to make sure these tests are accurate and consistent. This standard specifically calls for xenon arc lamps to simulate natural daylight, often referred to as D65. But what if a different lamp, like a Mercury Blended Tungsten Lamp (MBTL), is used instead? Let's dive into the differences and why it matters.