Opaque but Transparent - New low cost polymer for infrared lenses

Thermal and infrared imaging are used across industries including aerospace, defense, security and surveillance, medicine, electrical engineering, space exploration and autonomous vehicle operation.

How Infrared Imaging Works

The infrared or thermal imaging system consist of 3 main components

- Optics or lenses: Allows and focuses infrared radiation

- Infrared Detection: Captures object heat and converts heat to electrical signal.

- Signal Processing: Creates thermal images

Lenses

IR Lenses concentrate incoming infrared radiation onto the thermal sensor, making the camera more effective in capturing temperature variations. The most widely spread, but not the only, material used for manufacturing objective lenses of thermal imaging devices is single-crystal germanium, chalcogenide glass is also commonly used. To a certain extent sapphire, zinc selenide, silicon and polyethene also possess transmissivity in the MWIR and LWIR ranges. Optic germanium possesses high transmittance and a respectively low absorption coefficient in the range 2 – 15 µm. It is worth mentioning that this range covers two atmospheric transparency windows (3 - 5 and 8 - 12 µm). Most detectors used for civilian and military purposes operate in this range.

High Cost

Germanium is an element in short supply and with a hefty price tag – lenses made with it can cost thousands of dollars – while chalcogenide glasses are often made using toxic elements such as arsenic or selenium.

The New Polymer

A group of scientists at Flinders University in Australia has come up with a solution to make lenses using a new type of plastic. They used two very common and cheap materials, sulfur and cyclopentadiene, to create this plastic. Sulfur is found in large quantities during petroleum refining, and there's also a lot of it in the ground. Cyclopentadiene is made from low-cost materials found during petroleum refining. The scientists mixed these materials together in a special machine to create a black plastic that can let a specific kind of light through. They made it in a way that was never done before by other researchers. This plastic can then be shaped into different kinds of lenses. This method is much faster and cheaper than traditional ways of making lenses, like milling. In fact, making a small lens from this new plastic costs less than one cent.

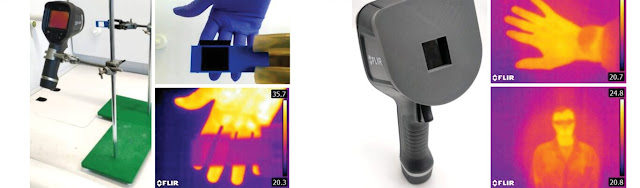

From the image, it can be seen that the polymer is transparent to the IR radiation. Images are taken with a thermal imaging camera. On the left side, the image behind the black lense is visible. On the right side, the complete image is taken by keeping the lense in front. The black color of the polymer could also make it useful for hiding thermal imaging equipment, like in surveillance situations, the researchers mention.