Xenon Arc vs. MBTL Lamps for Color Fastness Testing

When we talk about the color fastness of textiles, especially how they react to light, the type of light source used for testing is very important. Standards like BS EN ISO 105-B02:2014 are in place to make sure these tests are accurate and consistent. This standard specifically calls for xenon arc lamps to simulate natural daylight, often referred to as D65. But what if a different lamp, like a Mercury Blended Tungsten Lamp (MBTL), is used instead? Let's dive into the differences and why it matters.

The Gold Standard: Xenon Arc Lamps

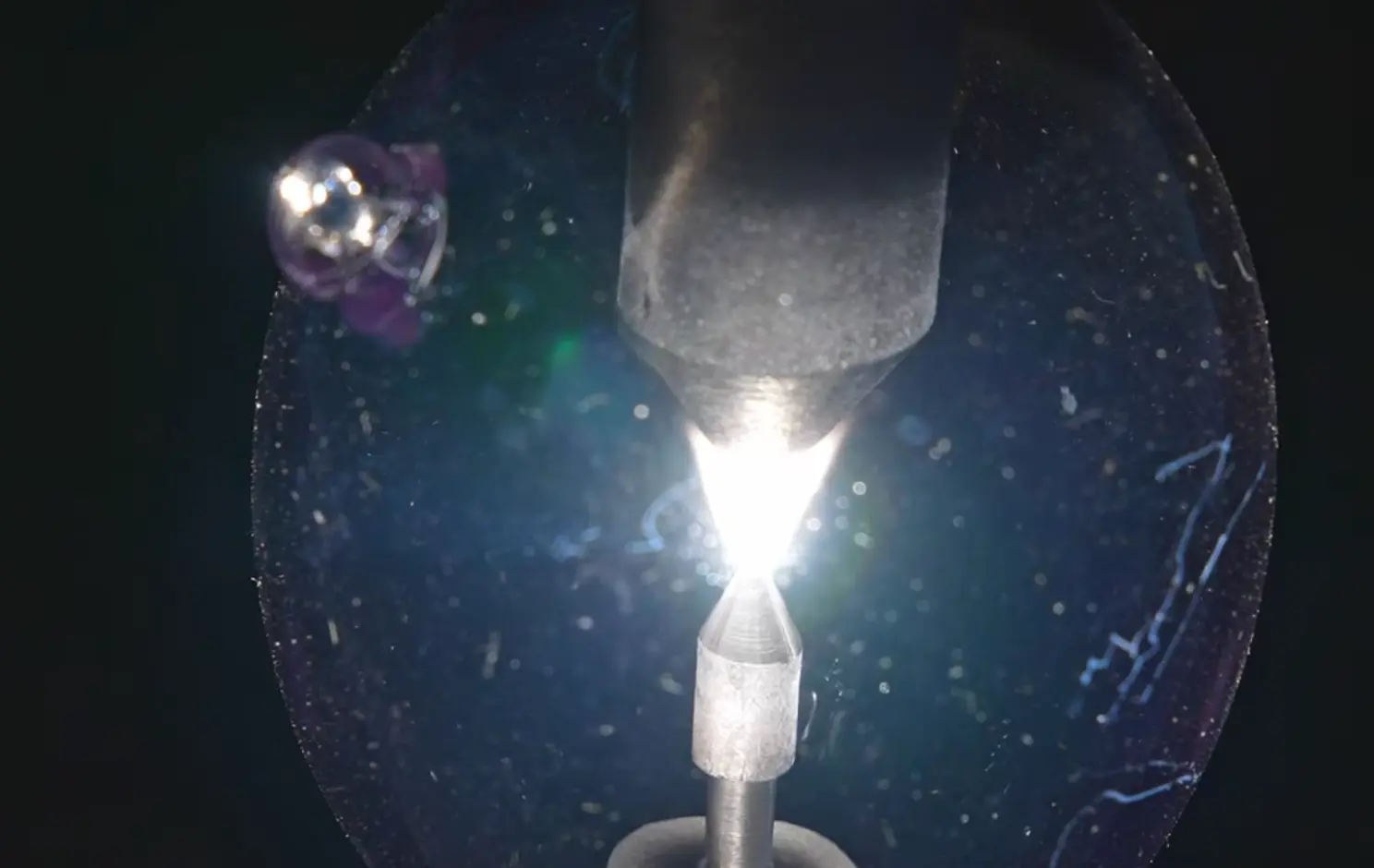

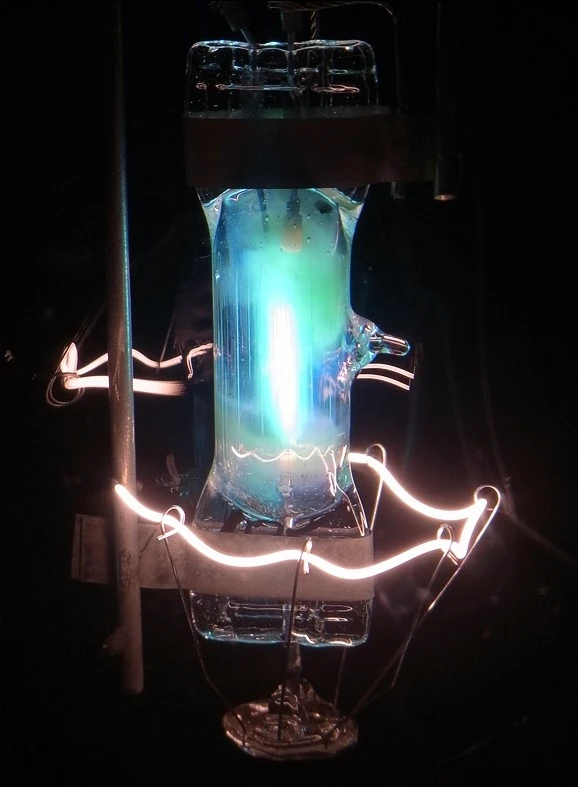

The ISO 105-B02:2014 standard is pretty clear about its requirements for light sources. It mandates xenon arc exposure devices, which can be either water or air-cooled. These lamps are chosen because they can closely simulate natural daylight (D65). Here’s what the standard looks for:

- Correlated Colour Temperature (CCT): A xenon arc lamp should have a CCT between 5500 K and 6500 K. This range is crucial for replicating the color temperature of natural daylight.

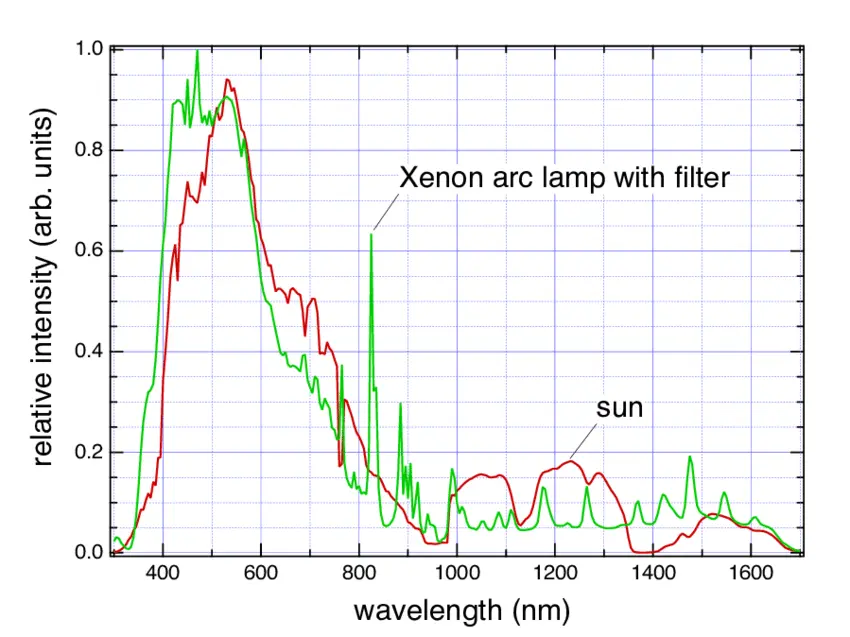

- Spectral Irradiance and Filters: Xenon burners naturally emit a lot of short-wavelength UV radiation, below 310 nm. To accurately simulate daylight, appropriate filters are used. These filters ensure that the spectral power distribution matches solar radiation, especially in the UV and visible regions. They also help in removing unrealistic UV radiation and controlling sample temperature by attenuating infrared (IR) radiation.

- Irradiance Uniformity: The exposure device needs to make sure the light is uniform across the specimen. The variation in irradiance shouldn't be more than ±10% of the mean. This often involves revolving racks for vertically mounted lamps and periodic repositioning of specimens for consistent results.

- Irradiance Control and Measurement: These devices come with starters and control equipment for adjusting the lamp's wattage, either manually or automatically. If automatic control is there, it uses radiometers to maintain specific irradiance levels, like 42 ± 2 W/m² in the 300 nm to 400 nm range.

- Maintenance: Regular replacement of lamps and filters as per the manufacturer's instructions is key to maintaining accuracy.

A xenon arc lamp gives a broad, continuous spectrum across the UV-visible range, which is exactly what we need to accurately mimic sunlight's effect on materials.

The Challenger: Mercury Blended Tungsten Lamps (MBTL)

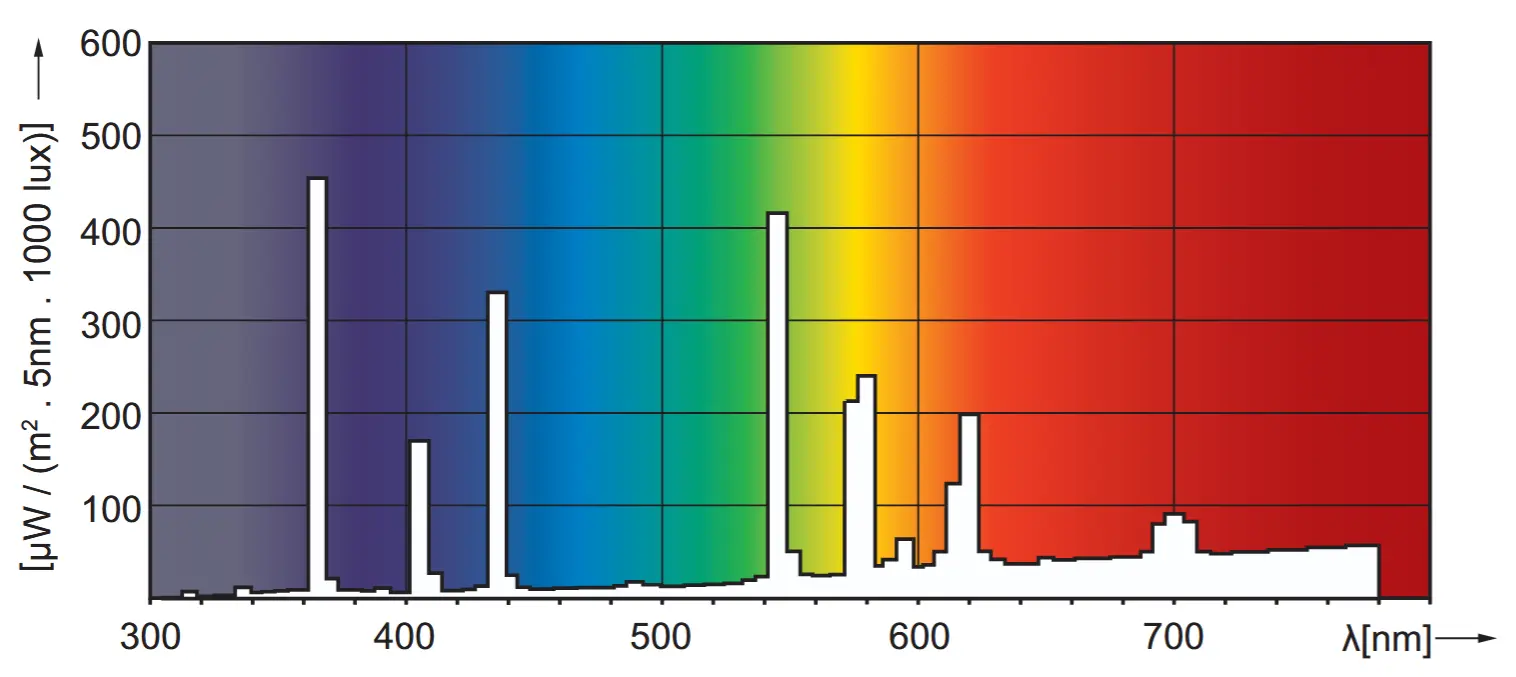

In domestic market we find a lot if light fastness equipments using 500W Mercury Blended Tungsten Lamp (MBTL) that claim compliance with test method IS 2454, which is stated to be per ISO 105 B02. However, when we look at the spectral characteristics of MBTL lamps, we find some significant differences.

Let’s take an example: a Philips Mercury Blended ML 160W Clear lamp.

- Its Correlated Colour Temperature (CCT) is around 3800 K. This is much lower than the 5500 K to 6500 K range mandated by ISO for D65 simulation.

- The Colour Rendering Index (CRI) of this MBTL is 60 Ra, while a D65 simulator has an Ra of 96. A lower CRI means it's not very good at rendering colors accurately.

The spectral power distribution of MBTL lamps is also quite different. They show distinct spectral spikes, which are characteristic of mercury vapor discharge, superimposed on a continuous spectrum from the tungsten filament. This is in stark contrast to the smooth, continuous spectrum of natural daylight and filtered xenon arc lamps. You'd see prominent spikes, especially in the blue (around 430-440nm) and yellow-green (around 540-580nm) regions.

Using an instrument that relies on an MBTL lamp would not accurately simulate the D65 daylight spectrum required by the ISO 105 standard. The pronounced spikes and lower color temperature would likely lead to inconsistent and unreliable color fastness test results. Materials would react differently to this altered spectral signature compared to true daylight or a compliant xenon source.

Recent Developments in Light Fastness Testing

In the realm of textile testing, continuous innovation aims to improve accuracy and efficiency. For instance, recent advancements in LED technology are also being explored for light fastness testing. While not yet a direct replacement for xenon arc in all ISO standards due to spectral matching challenges, researchers are developing LED-based systems that offer more control over specific wavelengths and energy efficiency. These developments aim to mimic the D65 spectrum more closely, potentially offering alternatives in the future, but currently, xenon arc remains the prescribed standard for its proven ability to replicate natural sunlight.

Wrapping Up

For accurate and reliable color fastness testing of textiles according to ISO 105-B02:2014, xenon arc lamps are the mandated and most suitable choice. Their ability to closely simulate the spectral distribution, CCT, and irradiance uniformity of natural daylight is unmatched. While other light sources like MBTL lamps might seem like an alternative, their fundamentally different spectral characteristics can lead to inaccurate and unreliable test results, compromising the integrity of your material assessments.

Happy Testing!