BNNT - The secret ingredient in space exploration

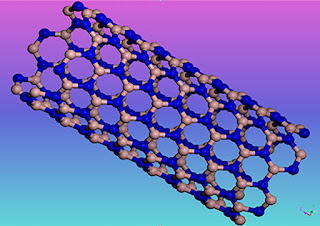

In the realm of nanotechnology, the discovery and exploration of nanotubes have opened up a world of possibilities. Among the various types of nanotubes, one remarkable and promising member is the BNNT (Boron Nitride Nanotube). These fascinating nanomaterials are rapidly gaining attention in scientific circles due to their exceptional properties and potential applications

What Are They?

Boron Nitride Nanotubes are tubular structures composed of boron and nitrogen atoms, forming hexagonal arrangements similar to carbon nanotubes (CNTs). The key difference lies in the atoms present; BNNTs consist of alternating boron and nitrogen atoms, while CNTs are composed of carbon atoms.

Unique Properties of BNNTs

BNNTs are some of the strongest materials known, with a tensile strength that is comparable to that of diamond. This makes them potential candidates for use in applications where high strength and stiffness are required, such as in composites and structural materials. In general, BNNTs have a tensile strength of up to 33 GPa, which is about 100 times stronger than steel.

BNNTs have a high thermal conductivity, which is similar to that of copper. This makes them useful for applications where heat dissipation is critical, such as in electronics and thermal management devices. In general, BNNTs have a thermal conductivity of up to 2400 W/mK, which is about 10 times higher than that of carbon nanotubes

BNNTs are electrical insulators, which is in contrast to carbon nanotubes, which can be either metallic or semiconducting. This makes BNNTs attractive for applications where electrical insulation is required, such as in electronic devices and sensors.

BNNTs are chemically inert, which means that they are resistant to corrosion and oxidation. This makes them useful for applications in harsh environments, such as in the aerospace and chemical industries.

BNNTs have piezoelectric properties, which means that they can generate an electric current when they are subjected to mechanical stress. This makes them potential candidates for use in sensors and actuators.

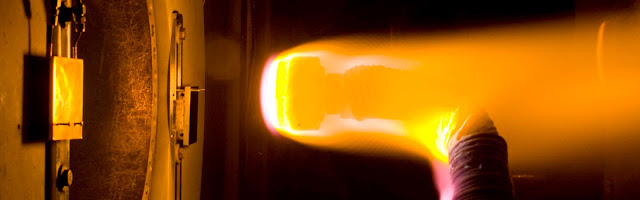

BNNTs can be used in high temperature environments, since the oxidation temperature of BNNTs exceeds 800°C

According to NASA - it's next generation radiation resistant, high strength, thermally stable, and ultra-light materials that are required for manned deep space exploration. Tiny tubes with great potential.

Kamlatech Innovate with us!