Electro-osmosis In Textile

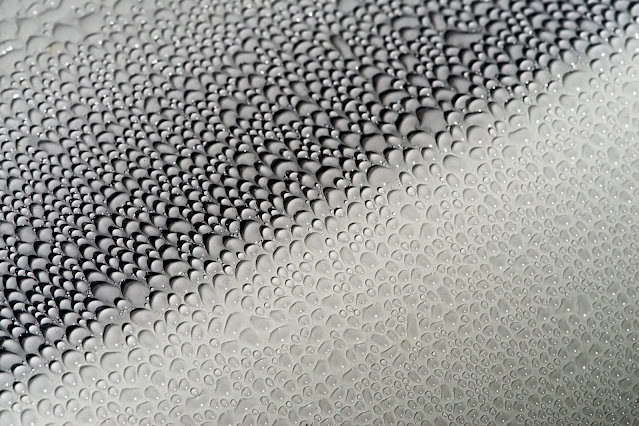

Electro-osmosis in textile membranes is a fascinating process where an electric field drives the movement of fluids through a textile material. But what exactly are textile membranes? These are porous materials made up of fibers or a matrix that allows fluids to pass through, and they’re widely used in applications like filtration and separation processes due to their ability to selectively move liquids.

Now, when we talk about how electro-osmosis works, we must consider the principle behind it: when an electric field is applied across a textile membrane—especially one with charged surfaces or in contact with an electrolyte solution—electro-osmotic flow can occur. This flow results from the interaction between the electric field and the electric double layer (EDL) that forms at the membrane's surface.

So, what is this electric double layer? It forms when the membrane is in contact with an electrolyte solution, causing ions from the solution to accumulate at the surface, creating a double layer of charges. This layer is essential because it interacts with the applied electric field, enabling the electro-osmotic flow. As the electric field exerts a force on the ions in the EDL, they begin to move, and this movement drags along the surrounding fluid molecules—like water or other solvents—resulting in fluid flowing through the membrane. Finally, you might wonder about the applications of this process. Electro-osmosis in textile membranes can enhance filtration efficiency, facilitate desalination processes, and control liquid flow in microfluidic devices. It's particularly valuable in fields that require precise control over fluid movement, making it a versatile and essential technology in various applications.

Innovate with Kamlatech