Sustainable Stretch Filaments NEOLAST™

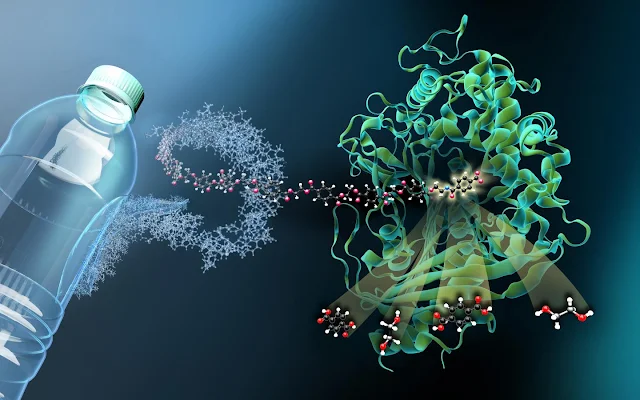

NEOLAST™ fiber is designed to revolutionize performance stretch fabrics, offering a sustainable alternative to traditional elastane, commonly known as spandex.

NEOLAST™ fiber is designed to revolutionize performance stretch fabrics, offering a sustainable alternative to traditional elastane, commonly known as spandex.

Standardizing woven fabrics, for comparison, can be done, by using parameters like fabric degree of tightness. This facilitates the creation of similar fabrics with variable construction parameters while predicting beat-up resistance in weaving. Standard fabrics offer advantages like design flexibility, predicting fabric properties, and aiding in specific end-use constructions, ultimately impacting weaving efficiency and fabric quality.

We all have some IoT projects in mind where we want to have a great visual communication with the users. TFT display are the best means if you want to convey the information visually in your absence. There are libraries for designing stunning GUI for TFT display, like

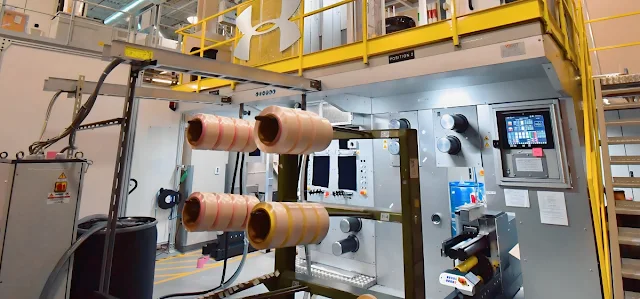

When we hear the word melt-blown, immediately we visualize a thin non woven used in a mask. Many of us are also aware that it is primarily made from Polypropylene (PP).It is normally supported by one or more spun-bond or melt-blown layer, but in general it is not stretchable and fragile to handle.

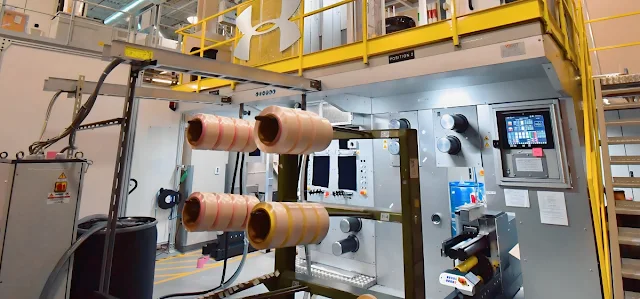

Thermal and infrared imaging are used across industries including aerospace, defense, security and surveillance, medicine, electrical engineering, space exploration and autonomous vehicle operation.

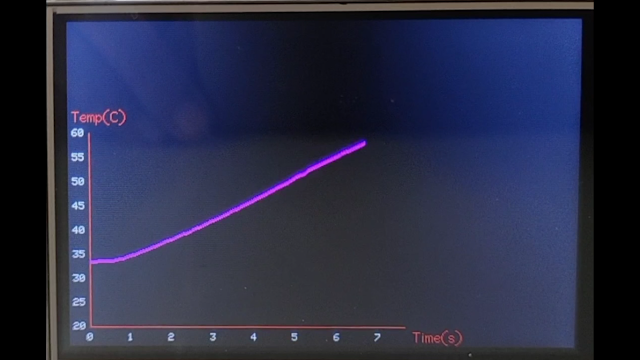

Plastic pollution is a global crisis that is wreaking havoc on our coasts and oceans. Among the many culprits contributing to this environmental catastrophe are plastic objects made from polyethylene terephthalate, or PET. These objects, once discarded, can linger in the environment for hundreds of years, causing harm to marine life and ecosystems. However, a recent scientific breakthrough offers a glimmer of hope in the fight against plastic pollution.

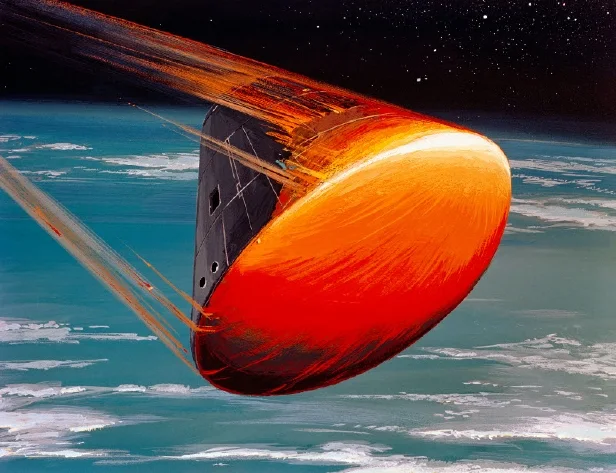

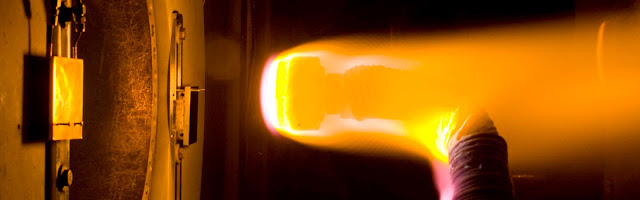

Ablative composites are specialized composite materials composed of high melting point fibers and polymeric resins that yield char at high temperatures. These composites are used in extreme environments, such as reentry vehicles like Gaganyaan, where they experience harsh conditions including high heat, pressure, and particle impact. These composites are made with reinforcements like carbon, graphite, silica, and glass, along with resins like phenolics and furfuryl alcohol.

Electrospinning is a technique used to produce nanofibers from polymer solutions or melts. The process involves creating an electric field between a liquid polymer source and a grounded collector, which results in the stretching and solidification of the polymer into ultrafine fibers as the solvent evaporates.

In the realm of nanotechnology, the discovery and exploration of nanotubes have opened up a world of possibilities. Among the various types of nanotubes, one remarkable and promising member is the BNNT (Boron Nitride Nanotube). These fascinating nanomaterials are rapidly gaining attention in scientific circles due to their exceptional properties and potential applications

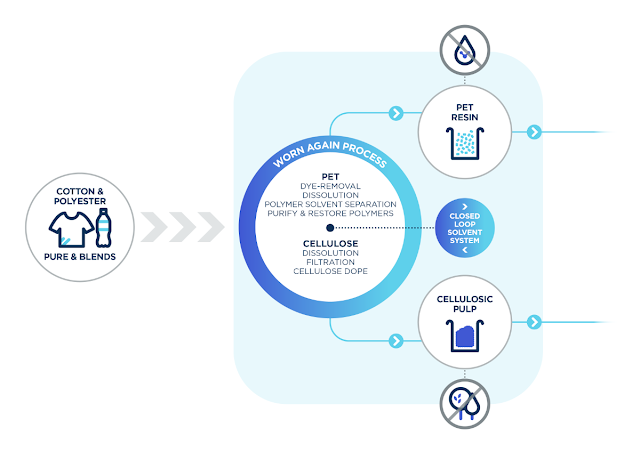

Separating cotton and polyester in a blended waste can be challenging. However, several chemical methods have been explored to facilitate the separation of cotton and polyester in textile waste.